Performance Refractories

You Can Trust

Refractories for Carbon-free Steel Ladle

Refractory solution for carbon-free steel ladle is developed specially to meet critical requirement by low- and ultra-low carbon steel making process. Refcer carbon-free refractories are high performance, environmental friendly and energy-saving materials, characterized with high strength, high erosion resistance to molten steel, good resistance to corrosion and penetration by molten slag, as well as long service life. As the products are manufactured with CAC, micro-powders or other inorganic additives as binders, no toxic gases are generated during pre-heating and application, and no extra hydrogen pick-up occurs. Moreover, there is no carbon pick-up by molten steel and comparatively better insulating performance, due to our carbon-free solution.

Generally, Refcer offers three types of carbon-free refractory products for steel ladle working lining,

(1) Castables: Castables are placed, cured and pre-heated on-site the steel workshop, and featured with joint-free and longer service life.

(2) Pre-cast Shapes: Castables are fabricated, cured and pre-heated at our manufacturing workshop and then delivered to the steel plant. Afterwards, these pre-cast shapes can be installed and put into use directly in the steel plants.

(3) Gunning Mixes: Refcer gunning mixes, which are carbon-free and recyclable, are placed by wet gunning technique and featured with characteristics of low cost, safe handling, eco-friendly, energy saving and long durability.

1. RCSL CAST Series Castables for Ladle Working Lining

RCSL CAST Series Castables for ladle working lining, manufactured with fused alumina, special grade calcined bauxite, magnesium aluminate spinel, fused magnesia as main starting materials, and featured with high strength, good volumetric stability and thermal shock resistance, excellent erosion and corrosion resistance, as well as long durability, are developed specially for sidewall and bottom working lining of large- and medium-sized steel ladles (slag zone are installed with MgO-C bricks ). And for small sized ladles, the RCSL CAST Series Castables are applicable for the whole working lining. In case of re-lining technique being used, service life of the ladle working lining can be further prolonged, and refractory consumption per ton of steel can be remarkably reduced.

Technical Data Sheet

1) B.D.: bulk density; C.C.S.: cold crushing strength; P.L.C.: permanent linear change;

2) Data shown are average results of standard tests unless otherwise noted. Results may vary subject to variations in manufacturing, testing, and installation procedures in the field.

2. Carbon-free Pre-Cast Shapes for Ladle Working Lining

Refcer Carbon-free Pre-Cast Shapes, with fused alumina, magnesium aluminate spinel and fused magnesia as main aggregates, are pre-fabricated in our workshop and delivered afterwards to the steel plant for direct use. These products are of excellent erosion and corrosion resistance, good thermal shock resistance and high service life, and applicable for bottom and sidewall working lining of large- and medium-sized steel ladles (for slag zone, MgO-C are used).

Technical Data Sheet

1) B.D.: bulk density; C.C.S.: cold crushing strength; P.L.C.: permanent linear change;

2) Data shown are average results of standard tests unless otherwise noted. Results may vary subject to variations in manufacturing, testing, and installation procedures in the field.

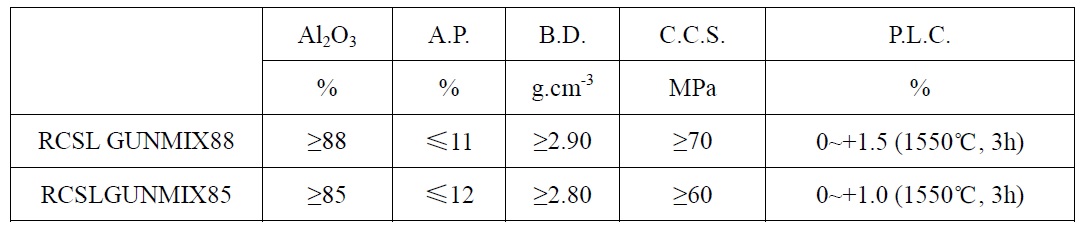

3. Gunning Mixes for Ladle Working Lining

RCSL GUNMIX products offered by Refcer are manufactured with fused alumina, magnesium aluminate spinel as major staring matereials. They are placed by gunning method onto the ladle working ling surface, with following benefits,

(1) Recyclable, low refractory consumption per ton of steel

(2) Highly automatic wet gunning technique, less toxic gases and good environmental friendliness

(3) Zero contamination to molten steel, low cost and high performance

Technical Data Sheet

1) A.P.: apparent porosity; B.D.: bulk density; C.C.S.: cold crushing strength; P.L.C.: permanent linear change;

2) Data shown are average results of standard tests unless otherwise noted. Results may vary subject to variations in manufacturing, testing, and installation procedures in the field.