Mould Fluxes

Refcere Mould Fluxes are engineered materials applied to the copper mold during the continuous casting steelmaking process, and play an important role in the end product quality and safety of the process. They are available in granular or powder form, and granular mould fluxes are our major products, which are sold under the brand name RCMFLUX.

RCMFLUX Mould Fluxes are casting granules for slabs, billets, blooms, thin slabs and beam blanks, and their applications cover the full range of steelmaking from different C grades to special alloyed and stainless steels. They are designed and tailor-made according to the operational parameters, steel grade and quality requirements for each customer to provide optimum functions as following:

- Lubrication between the solidified steel shell and the mould, to prevent the solidified surface of the steel from sticking to the mold.

- Thermal Insulation to avoid premature solidification of the liquid steel in the meniscus zone

- Control of heat transfer in the mold to prevent surface defects

- Absorption and dissolution of non-metallic inclusions for steel cleanliness

- Protection of the steel meniscus from re-oxidation

With over 20 years of technical innovation and extensive working experiences and know-how gained through close collaboration with our customers, in terms of in-plant testing and implementation, Refcer has developed and is offering an extensive range of mould fluxes that satisfy the highest of casting process requirements by our steelmaking customers all over the world.

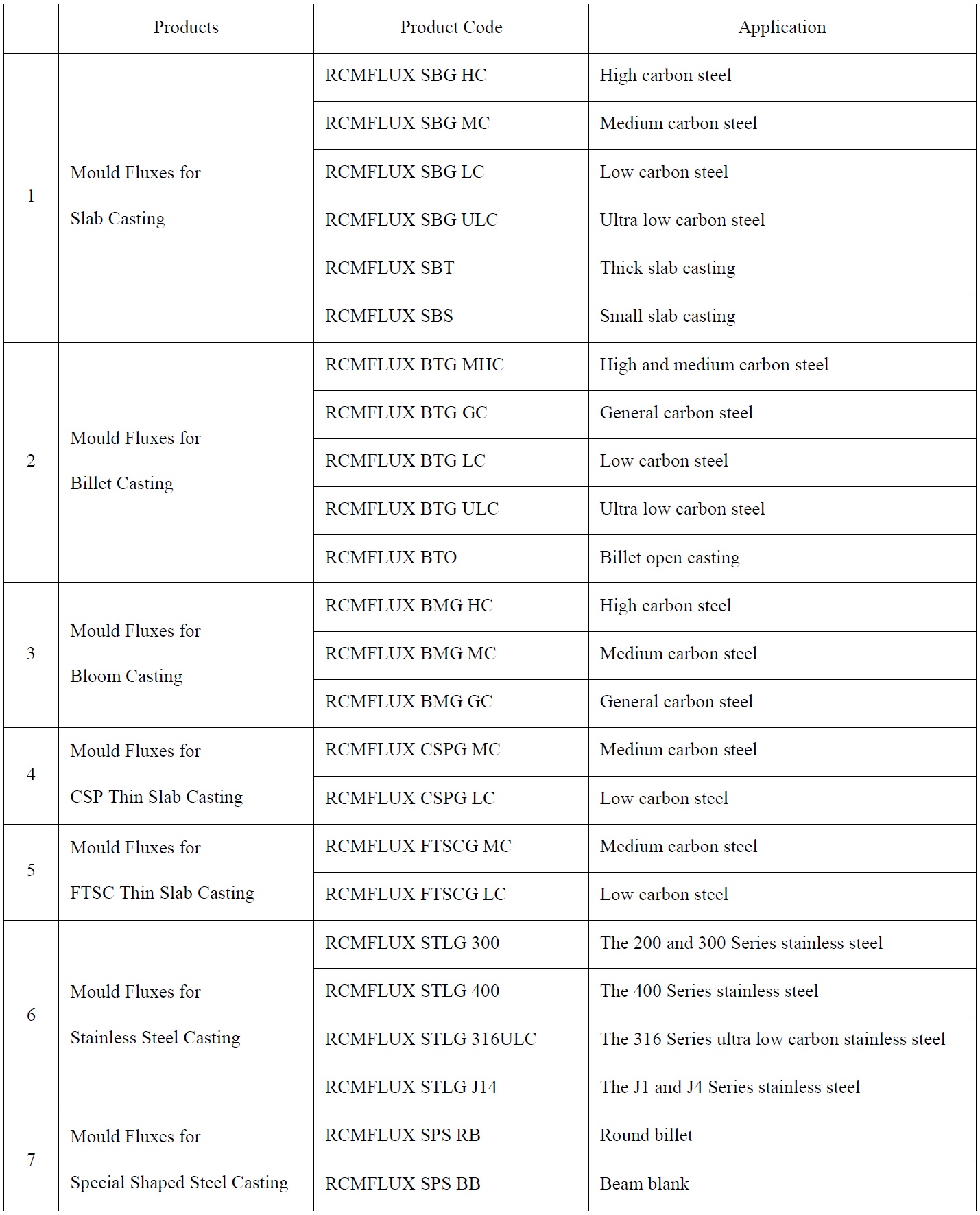

RCMFLUX Mould Fluxes Products Offered by Refcer